Muyo Elevated Bridge ~ seismic strengthening ~

2018.2.22

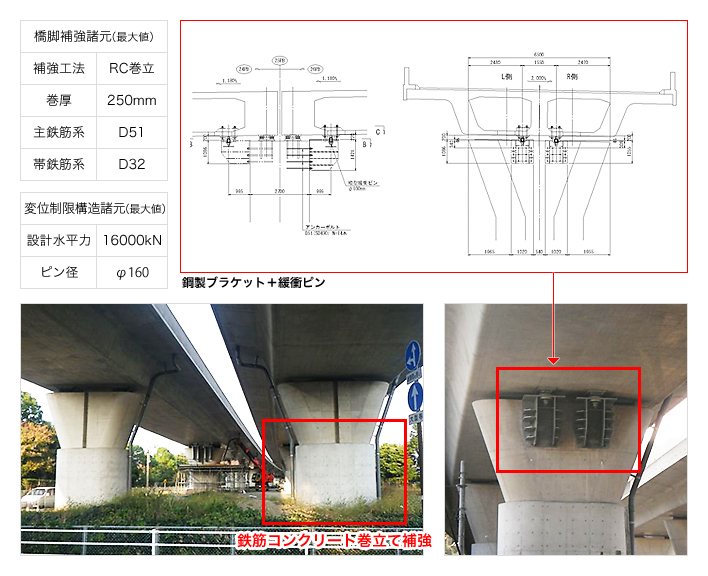

The work involved a seismic strengthening design for Muyo Elevated Bridge. EJEC proposed a method to disperse the seismic force to all of the bridge piers while protecting the shoes by means of fixing the existing stress dispersion piers while rationalizing the reinforcing elements by reducing the number of fixed points. As this bridge has a total of 68 piers to support the inbound and outbound lanes, rationalization of the strengthening of each pier can produce a large difference when totalized. As such, careful attention was paid to the details of the strengthening method to reduce the cost of the strengthening work. One example of rationalization was a reduction of the number of drilling sites by reducing the number of anchor bolts with the use of a high strength material. For the design of the strengthening work, dynamic analysis using a space frame model was used.

The prominent technological feature of the work is the introduction of a displacement restriction structure with multiple fixing points to protect the existing rubber shoes so that the changed conditions for the supporting points could rationalize the strengthening work while securing the aseismatic resistance of the entire bridge. As the bridge is a PC box girder bridge, the heavy weight of its superstructure increases the seismic force acting on each support point. A large number of parameter studies with dynamic analysis were, therefore, conducted to achieve optimization of the strengthening work so that the number of fixing points could be reduced as much as possible.

| Route name | Kobe-Awaji-Naruto Expressway |

| Work title | Checking of the Aseismatic Performance of Muyo Elevated Bridge and Another Bridge, Seismic Strengthening Design of Muyo Elevated Bridge and Others |

| Location | Tokushima Prefecture |

| Duration | FY 2010 to FY 2012 |

| Implementing body | Honshu-Shikoku Bridge Expressway Co., Ltd. |

Eight-Japan Engineering Consultants Inc.

Eight-Japan Engineering Consultants Inc.- All News

- Seismic Resistant & Disaster Prevention

- Muyo Elevated Bridge ~ seismic strengthening ~